How a new print technology can improve quality, speed – and sustainability

Quality and sustainability can work together when teamed with the latest print technology

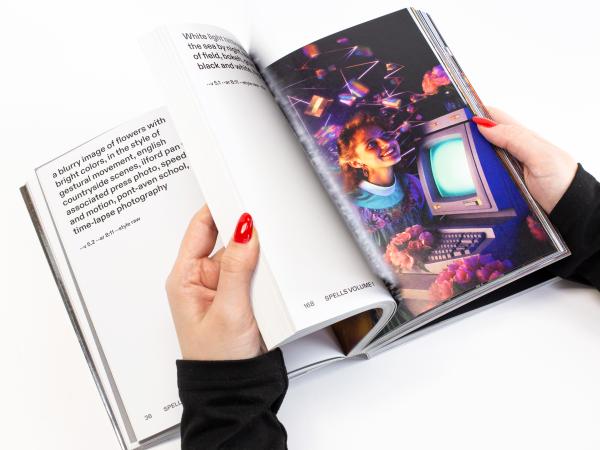

Trifolio, the go-to printer for high-end art books, has always held print quality at the core of everything it does. An early adopter of LED-UV technology, they recently upped their game by introducing a second LED-UV lamp as part of the production process.

Based in Verona, Italy, the company produces art books for the likes of the Museum of Modern Art and the Metropolitan Museum of Art in New York City, Princeton and Yale universities and leading galleries such as Dominique Lévy and David Zwirner. Such clients are demanding – and Trifolio is always searching for ways to improve and refine its limited-edition runs. As part of that, achieving the best possible colour reproduction is crucial.

Higher print quality and faster production speed

Trifolio has been using LED-UV curing since 2017, after owner Massimo Tonolli saw a demonstration of the print innovation and recognised its potential. “Museums and galleries can go through one, two, three, four proofs to go on press,” Tonolli told ARTnews magazine.

“The fidelity of the colours is extremely important, and the quality of the dots on paper with LED UV is amazing.”

The second lamp has been installed to fix the first layer of ink on the printed surface before overprinting it on the next unit. "The result is much better – with the extra lamp drying the first layer," said Tonolli.

Although LED-UV is now widely recognised as producing images of higher quality, for printers like Tonolli the print technology was initially a difficult sell. Traditional UV systems had a reputation for producing books that smelt when opened because of the inks they used. “We had to explain that LED is a technology without that odor,” as well as being one that provides “superior quality and faster production speed”.

Stronger sustainability and safety benefits

Another key benefit of LED-UV comes with its environmental credentials. To begin with, it produces less heat and requires less power. Unlike traditional arc lamps that have to remain on during the whole production process, LED lamps only need to be switched on when needed, and don’t require a warm up period.

LED lamps are also free of the mercury found in arc bulbs (which is potentially hazardous to employees and requires special disposal) and have the benefit of providing longer lifetime use (an average of 10 times longer, according to one manufacturer).

Another environmental advantage is that the special inks used for the LED-UV process are free of solvents, meaning that they don’t release potentially dangerous, volatile organic compounds. And because the inks sit on the substrate, rather than soaking into it, less ink is required to do the same job. When using offset presses, meanwhile, there’s also no need to use a drying powder – resulting in a cleaner, more efficient printing process.

For Tonolli, LED-UV has been a game changer: “Innovation is the key to discovering print solutions compatible with the realization of a book of exceptional originality."

Sources:

https://www.artnews.com/art-news/sponsored-content/trifolio-high-end-ar…;

https://www.amsspectraluv.com/about-led-uv-1

Image credits: Trifolio