Success through strong partnerships: A Magno papers case study for high-speed inkjet printing

In today’s printing industry, the trend is towards high-speed inkjet. Thanks to flexibility and ease of customisation, it can meet changing market requirements. We spoke to Christian Haneke, Innovation & Solutions Manager at Sattler Premium Print, about the beta test of the world's first high-speed inkjet web press Ricoh Pro VC 80,000 with Magno papers.

Challenges to overcome

When water-based inkjet printing is used on coated paper, a technology designed to allow ink to penetrate the paper is used on paper with a closed surface.

"Ten years ago, this was a major hurdle for water-based inkjet, because customers wanted a choice of paper that was comparable to the printing technologies they were familiar with".

To be able to implement product ideas from customers at short notice, a clever selection of house papers is also important.

Furthermore, in high-speed inkjet printing, paper-specific settings often have to be made on the printing presses, because, "In order for me to achieve consistent print quality with inkjet printing, it is particularly important that the quality and formulation of the paper is extremely stable and predictable – even over a longer period of time."

Haneke and his colleagues have an extraordinary variety of technologies at their disposal at the Bad Oeynhausen site in Germany. This innovative approach also convinced Ricoh, who selected Sattler Premium Print last year for the world's exclusive beta test of its new Pro VC 80,000 inkjet printing platform. At Sattler, it is placed not only next to sheetfed and web offset presses, but also next to the Ricoh VC 70.000, which is also in operation.

With hybrid products produced through different machines as well as printing technologies such as offset and inkjet printing, it is important for Haneke that the customer ends up with a harmonious-looking product.

The Magno papers solution

Haneke was completely satisfied with the performance of the Magno papers: "It has to be said that the VC 80,000 has some technical delicacies in store. Compared to the VC 70,000, we often run the press at a higher printing speed."

"This means that the paper must work in terms of runnability, and the drying behavior of the printing ink must work at high speeds. Here, Ricoh has taken a noticeably big step forward with the dryer. Sappi Magno Web Silk and Sappi Magno Web Gloss are the papers that we often use in the coated area, and they worked great on the machine. We now have the option to print with 300 gsm paper at higher speeds. We have also tried this with glossy papers, where there is often a loss of quality in high-speed inkjet. That also worked great with Magno."

For Haneke, a strong paper partner at his side is crucial to success:

"It is extremely important for us to have reliability in the paper portfolio and, of course, in product quality. We are dependent on partners like Sappi, who have understood that the topic of high-speed inkjet will play an increasingly important role in the future."

The market for graphic paper manufacturers is undergoing a consolidation process. Companies are trying to position themselves for the future. "It is important for us that the partners we have are and remain strong, and that we are in close contact with them. This way we know at an early stage what is happening and can bring in the points that are important to us," says Haneke.

Takeaway

The successful collaboration between Sattler Premium Print, Ricoh and Sappi shows the importance of a strong partnership to create a high-quality product for end customers. For Haneke, this is key. "I believe that this coming together in the industry – to be in a very close exchange – with great transparency and reliability, is of essential importance," he says.

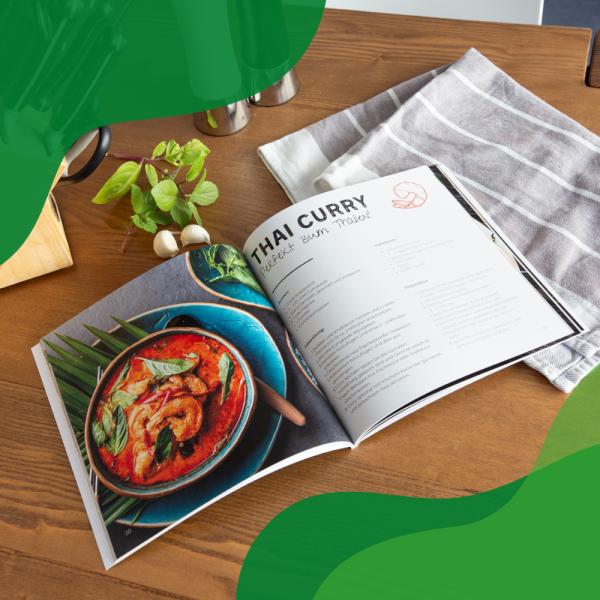

A good example of this innovative collaboration is the cookbook “Easy Peasy” recently published on the occasion of the first in-house exhibition of the Sattler Media Group. The cover was printed on Magno Satin 350gsm in sheet-fed offset and the contents on Magno Web Silk 170gsm using high-speed inkjet printing.

If you want to convince yourself of both the technology of the Ricoh VC 80.000 and our premium paper Magno with your own hands, you can order the cookbook by filling in the form below.

About the company: Sattler Premium Print, based in Bad Oeynhausen, Germany, has been part of the Sattler Media Group since the end of 2020, is dedicated to printing high-quality print products in the catalogue and magazine sectors. This means individual print productions in terms of content, colour, format and processing – and also individualisation of content, including through the high-speed inkjet process.